Water Access in Emergencies

Practical Action

Wells & Boreholes

In any scenario with groundwater, it is likely that the majority of it will exist in the water table

below the surface. If there are no springs, or they are not able to meet supply, wells and boreholes

must be dug to reach the water.

The locating of a well can be difficult if the geology of the sub-terrain is unknown. Expertise can

be sort from a hydrogeologist if available, but often it requires luck and several attempts to find

an area of water table with sufficient yield. Refer to WEDC’s guide on Emergency Water Sources

for detailed information and checklists on the siting of groundwater sources.

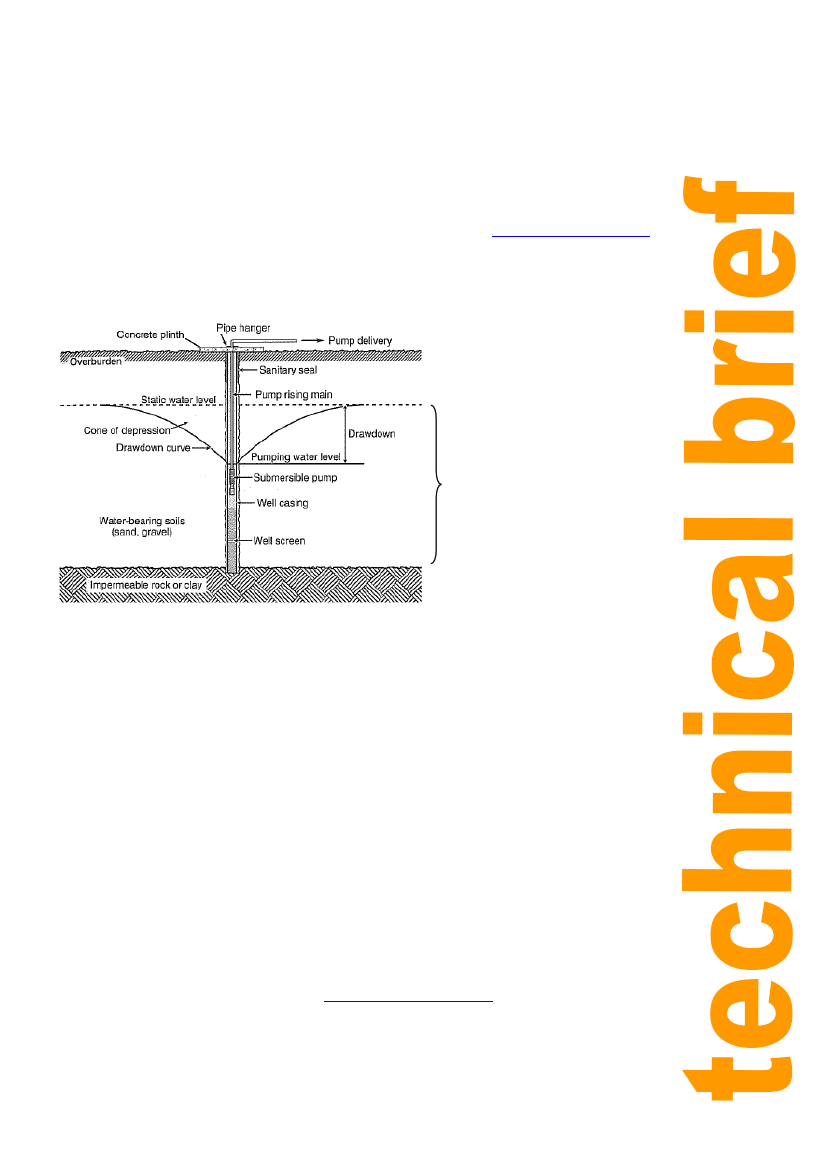

Typical Features

The picture below demonstrates the main features of a well:

Aquifer – water is drawn down to

the pump level, below the static

water level

Figure 11: Schematic diagram of a typical well

Source: Davis, J. and Lambert, R. (2002)

The well will typically have a screen extending down its length into the water-drawing area, to

reduce sedimentary intake to the pump. The hole will have an impermeable casing at the upper

end, to prevent contamination, often made of bricks or concrete rings. The well will be sealed at

the top to prevent dirty water or pollution entering. These features may differ depending on the

geological conditions and the height of the water table.

Options for well construction

There are several methods for constructing a well, ranging from hand-digging to drilling with

industrial machinery. The most practical method depends on a range of factors, including ground

condition, supply requirements, yield, geology, manpower and machinery available.

In general, hand dug or drilled wells can be constructed quickly, requiring only manpower and

simple tools. However, the depth to which they can be dug is limited to approximately 30m in

normal conditions (Davis, J. and Lambert, R. (2002)). Additionally, hand-powered machinery is

either slow or unable to dig through difficult ground.

Machine drilling can be much quicker, and is capable of drilling boreholes through harder ground

to much deeper levels. The requirement to import specialist machinery to achieve this results in

an increased cost. Drilling methods are traditionally divided into ‘percussion’ (repeated beating of

ground by drill-piece) and ‘rotary’ (conventional rotation of cutting tool) drilling, although a

combination of both can be used. Refer to Engineering in Emergencies for information of several

methods of drilling and well lining, and their corresponding advantages and disadvantages.

9